Cathodic protection systems are a method of corrosion control used to protect metallic structures. Using these systems can extend the service life of a structure by a great deal, and they can be tested regularly to ensure their efficiency. These systems have been used in a variety of applications for many years and are generally installed during the original construction of a structure, as well as during major expansions or upgrades. Here are some of the advantages of cathodic protection:

The most common application of CP systems is on water-cooled turbines. This type of corrosion protection works by redirecting corrosion reaction to anode. It can also be used on non-metallic vessels to protect outboard motors. The most common type of CP system is passive, meaning that it doesn’t require a power source. However, passive systems do require an external power source. These types of cathodic protection are a good choice for smaller boats or those with non-metallic hulls.

Cathodic protection systems are most effective when they protect pipelines from corrosion. It protects water storage tanks, steel piles, and offshore oil platforms. It also helps prevent stress-corrosion cracking and other damage to the structure. The use of these systems is widespread in the oil industry. Some of the most common installations are in water storage tanks. Moreover, they can be used in power plants. And, because they are so effective, they are also extremely low-cost.

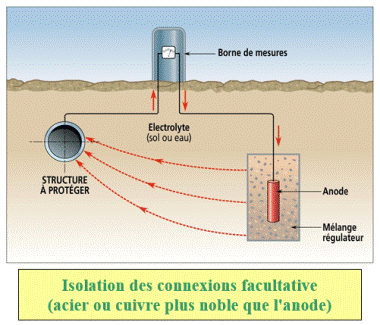

Another application for cathodic protection systems is on steel storage tanks and pipelines. These steel pipes are common in many parts of the world. The corrosion they encounter are constantly being threatened by soil, electrical interactions with the surrounding infrastructure, and even the underside of storage tanks. Most commonly, specialized coatings and vapor corrosion inhibitors are used to protect these assets. In addition, cathodic protection systems are used as a secondary protective measure.

In addition to a pipeline, a cathodic protection system can also protect tanks and vessels. This type of system can be applied to tanks and vessels. Moreover, the cathodic protection system is used in offshore production platforms and water treatment plants. For instance, it can be installed in steel rebar and shells. The cathodic protection systems are effective in protecting a large number of types of metallic and non-metallic structures from corrosion.

A cathodic protection system has two different types of anodes. One is made of a solid material called anode metal. The anode is used to provide resistance to corrosion. It is a vital part of a water-damaged vessel. It is critical to ensure that the cathodic protection system is properly installed. It is important to avoid any possible corrosion of electrical equipment and cables.

During an installation of a cathodic protection system, a sacrificial anode must be used. These anodes are made of metal. The anode should be made of metal with high corrosion resistance. A sacrificial anode will also be more active than the steel. It is essential to make sure that the anode is strong enough to withstand a high amount of corrosion.

A cathodic protection system requires an anode with a lower electrode potential than the target material. Anodes for ICCP systems can range from simple lead wires to AC coupons. The anode should be smaller than the target material. A good anode will allow you to test a structure with the least amount of trouble. This type of anode can be used to protect a facility without a complex installation.

A cathodic protection system is very effective. When the anode is corroded, it can cause an explosion. A cathodic protection system protects a structure by lowering its electrical potential to a level that is conductive to anodes. These systems are also useful for preventing damage to electrical components. If you have an electrical component, a cathodic protection system can be a very effective way to prevent corrosion.

The design of cathodic protection systems is crucial to the effectiveness of these systems. A cathodic protection system is a blueprint for installation. The expert who created the design will examine your ship’s structure and its metallic materials. By following this blueprint, the anodes will protect your steel structure and propeller. You can download the cathodic protection system designs from the internet. They are highly helpful.

Comments are closed.