A carton sealer is required by businesses that package their products in cartons. While an abundance of projects and duties may appear daunting at first, it usually signifies those clients are spending their money with you, so revenues are increasing. Your decision will have an impact on the efficiency of your procedures. Too much work is one of the troublesome problems a company can have.

Some of the time-consuming and mundane processes in your warehouse can be automated to help improve throughput and productivity, allowing your team members to focus on the more critical jobs that demand extra focus or involvement.

Carton sealing is an example of this. Instead of your personnel wasting time manually applying tape to every box that leaves the building, you may hire an automatic case sealer to accomplish the job faster and more accurately. What’s the first step in making this a reality? It would be best if you chose a case sealer machine for the packaging requirements of your business.

Case Sealer Machine

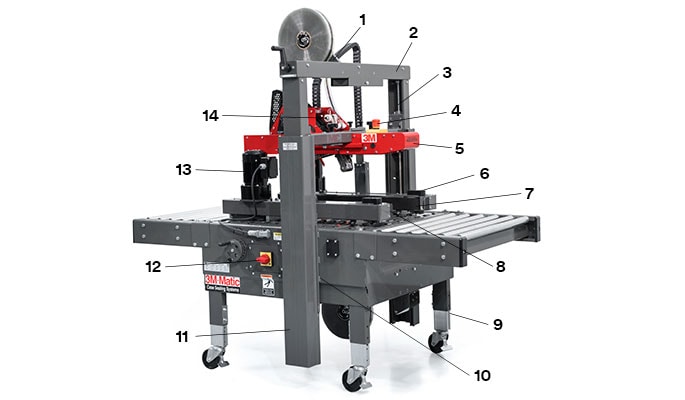

A case sealer, sometimes a carton sealer or a tape machine, is a relatively simple piece of packaging machinery. When in use, it transports a case or box down a conveyor and via two tape dispenser cartridges. As the cartridges go down the line, they apply the tape to your box, eliminating the need for manual tape.

Case sealers, also known as carton sealing machines, are packing equipment that folds and close the top lids of your filled cartons. After the packaging process, these machines provide a dependable and quick technique to seal cases.

A case sealer is a machine that applies tape to pre-packaged, ready-to-ship boxes. Applying tape to each box does not require your team members to waste time. You’ll be able to complete this work more efficiently and effectively if you use an automated case sealer. This machine will assist you in automating your business activities.

It’s also known as a carton sealer or a box taping machine. It transports a box or case down the conveyor system via two tape dispenser cartridges. As the box moves down the line, these cartilages will attach to the tape. It is one of the most brilliant innovations of our time.

You can improve the efficiency of your processes by using a carton sealer. Purchasing this technology is one of the best investments you can make in your company. In the long run, it speeds up and lowers the cost of the procedure.

Types Of Case Sealers

On the market, there are four different types of carton sealers. The uniform semi-automatic and random semi-automatic are two examples. The uniform fully automated and random fully automatic sealers are the other two. Let us go over each of them to give you a clearer idea.

Uniform Semi-Automatic Case Sealer

If you’re making uniform box sizes, this machine is ideal. An operator must fold the box flaps and then feed the carton into the machine.

The machines seal both the bottom and top of the box. The operator does not need to make any tool changes if you need to seal a different case size. As a result, operating this machine takes relatively little time and effort.

Random Semi-Automatic Case Sealer

When you need to tape multiple sizes of boxes one after another, the case sealer is appropriate. You’ll also need an operator to assist you with folding the case flaps and loading the boxes into the machine. This machine can accommodate a variety of case widths and heights. It also secures the box’s bottom and top portions.

Uniform Fully-Automatic Case Sealer

The machine is perfect for long runs of boxes of the same size. You won’t need an operator to fold the flaps in this situation. The top flaps are folded once the machine has been configured to specific case size. The bottom and top of the case are then sealed. The operator performs easy no-tool modifications if a different case size is required. Making these changes takes very little time.

Random Fully-Automatic Case Sealer

If you need to tape multiple boxes one after the other, this case sealer is a great option. An employee does not need to fold the box flaps in this scenario. Additionally, for random-size boxes and continuous runs, no setup is required. You start and run the various sized boxes because it is a completely automatic machine.

Things To Consider Before Choosing a Case Sealer Machine

Several criteria determine the ideal case sealer for your needs. It is significant to pay attention to each of them to make the best decision. Following are some of the points to consider before having a case sealer.

Case Size

Make a list of the case sizes you use, from the smallest to the largest. Check if the sealer you want to buy is compatible with all of these sizes. Important! Even within the same series of sealers, capacity might differ significantly from one model to the next.

Weight Of the Case

All sealers, regardless of brand, have a maximum capacity in terms of case weight that they can handle. Consider the weight of your products as well as the regulations of your industry when selecting a unit.

Working Environment

Where do you intend to put your case sealer to work? Do you prefer to work in a high-humidity atmosphere or a typical office setting? A stainless-steel case sealer is preferred if the equipment will be utilized in a high-humidity or food processing setting because it is better equipped for these situations.

If the case sealer is going to be utilized in a regular working environment, an enameled steel type will suffice. It’s also crucial to consider how much space you have for the equipment. Case sealers are available in a variety of sizes. Check first and avoid surprises!

Production Volume

The volume of cases to be sealed daily should be around 150 or higher to purchase a case sealer worthwhile. Once you’ve decided that this is the proper investment for your company, research the models most suited to your expected production volume. Check the maximum production rate of the equipment you’re considering to be sure it’ll be able to meet your future needs as well.