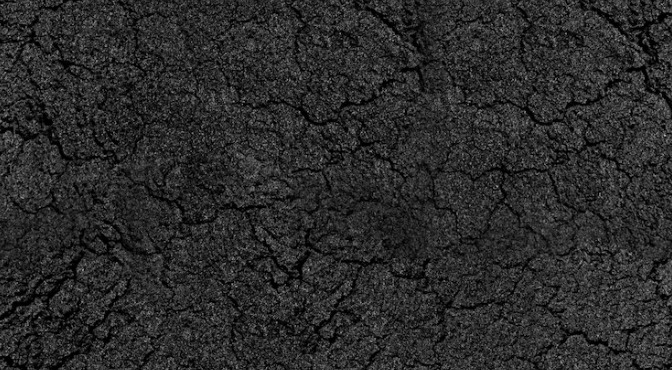

Cracks in asphalt surfaces are not only unsightly but can also lead to further deterioration if left unaddressed. Fortunately, asphalt crack fillers are specifically designed to repair and prevent the expansion of cracks, ensuring the longevity and integrity of your asphalt. In this article, we will explore different types of asphalt crack fillers and guide you through the process of applying them effectively.

What is Asphalt Crack Filler?

Asphalt crack filler is a specialized product used to repair cracks in asphalt surfaces. It is formulated to withstand the rigors of weather and traffic, preventing moisture penetration and minimizing further damage. Crack fillers are available in various forms, including liquid crack filler, asphalt patch, and hot pour rubberized crack filler, each serving a specific purpose in addressing different types and sizes of cracks.

Liquid Crack Filler

Liquid crack filler is a pourable solution that can be applied directly into smaller cracks, typically those measuring less than a quarter-inch in width. This type of filler is easy to use, as it can be poured directly from the container into the crack. It is ideal for DIY projects and minor crack repairs.

Asphalt Patch

For larger cracks or damaged areas, an asphalt patch may be necessary. Asphalt patching materials consist of a combination of asphalt binder and aggregate, providing a more robust and durable solution. These patches come in different forms, such as cold mix asphalt or ready-to-use pre-mixed patches. They are typically applied by hand or with the help of specialized tools.

Hot Pour Rubberized Crack Filler

Hot pour rubberized crack filler is a popular choice for repairing medium to large cracks in asphalt surfaces. This type of filler is heated to a specific temperature and then poured into the cracks using a crack filling machine or a pour pot. It offers excellent adhesion and flexibility, ensuring long-lasting repairs even in high-traffic areas. Hot pour crack fillers have excellent adhesive properties and can withstand extreme temperatures and weather conditions. One of the recommended hot pour crack fillers available at Asphalt Kingdom’s supply store is the Crack-Stix™ Permanent Crack Filler.

How to Apply Asphalt Crack Filler

The application process for asphalt crack filler may vary depending on the product and the size of the cracks. However, the general steps involved are as follows:

- Clean the cracks: Remove any debris, vegetation, or loose materials from the cracks using a wire brush or a high-pressure air blower. Clean, dry cracks ensure better adhesion and a more effective repair.

- Prepare the crack filler: Follow the manufacturer’s instructions to prepare the crack filler. This may involve heating the filler in a hot kettle or simply opening the container for liquid crack fillers.

- Fill the cracks: Pour or apply the crack filler directly into the cracks, ensuring that they are filled to the appropriate level. Use a trowel or squeegee to smooth the filler evenly across the crack surface.

- Allow curing: Allow the crack filler to cure as per the manufacturer’s recommendations. This may involve waiting for a specific drying time or ensuring proper temperature conditions for hot pour fillers.

Bulk Asphalt Crack Sealer

For larger projects or professional use, bulk asphalt crack sealers are available. These sealers come in larger quantities and are often more cost-effective. They are typically purchased in drums or totes and require specialized equipment for application.

To explore a wide range of high-quality asphalt crack fillers and related products, visit asphaltkingdom.com/supply-store Asphalt Kingdom’s Supply Store. Their product selection includes a variety of crack fillers suitable for different project sizes and requirements. Remember to choose the right product based on the specifics of your crack repair project.

Conclusion:

Asphalt crack fillers play a crucial role in maintaining the integrity and longevity of asphalt surfaces by addressing cracks effectively. By understanding the different types of crack fillers available, such as liquid crack filler, asphalt patch, and hot pour rubberized crack filler, you can choose the most suitable product for your specific needs. Proper application techniques, including cleaning the cracks thoroughly and following manufacturer instructions, are essential for achieving successful repairs. Remember to consider the size and type of cracks you need to address when selecting the appropriate crack filler. By utilizing asphalt crack fillers, you can extend the lifespan of your asphalt surfaces and ensure their optimal performance.